Pressure Seal valves are used primarily, but not limited, to power generation plants with fossil, coal, thermal, gas, nuclear power plants, steam power stations, etc.

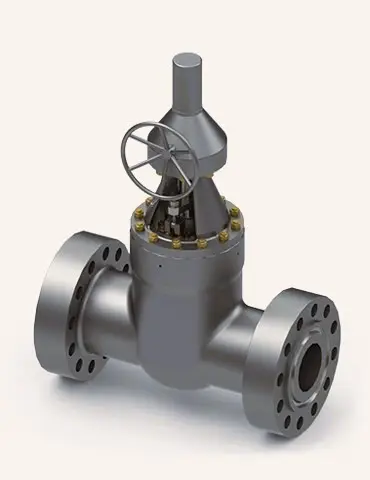

Pressure seal valves are excellent in the following conditions: high pressure, high temperature, steam, oxidizing environments, among others. One of the most important features of MICRONE Pressure Seal Cast Steel Valves is it ability to use the pressure line to assist in the seal of the valve with a preloaded metallic or graphite pressure seal gasket placed between body and bonnet which reduces weight for easy installation and maintenance increasing safety and seal of the body-bonnet joint.

Pressure Seal Valves are designed in accordance ASME B16.34. Pressure Classes 600, 900, 1500 & 2500 # and sizes from 2” up to 24” nominal diameter.

Design Features

- Design in accordance with ASME B16.34

- WE short pattern; RF & RTJ long pattern as per ASME B16.10

- Outside Screw & Yoke (OS&Y)

- Flexible wedge

- Option with Parallel Slide disc available upon request

- From 2” to 16” handwheel operated

- End to end dimensions as per ASME B16.10

- Flange dimensions as per ASME B16.5

- Weld end dimensions as per ASME B16.25

PRODUCT STANDARDS & SPECIFICATIONS

Valve Size

Valve Type

Pressure Class

End Connection

Operator

Material

Operating Temperature

Leakage Class

Design Standard

Face to Face Standard

End Connection Standard

Test Standard

Fire Safe Standard

Certification

2″ – 36″

Pressure seal Bonnet

ANSI 600 / 900/1500

RF / RTJ / BW / SW

Lever / Gear / Actuator

Carbon Steel / Stainless Steel / Duplex / Alloy Steel

Standard / High

API 598 / ANSI FC70-2 / ISO 5208

ASME B16.34 / API 600

ASME B16.10

ASME B16.10

API 6D / API 598

API 607 / ISO 10497 / API 6FA

EN 10204 3.1 – 3.2 / IP 67 (Gear Box)