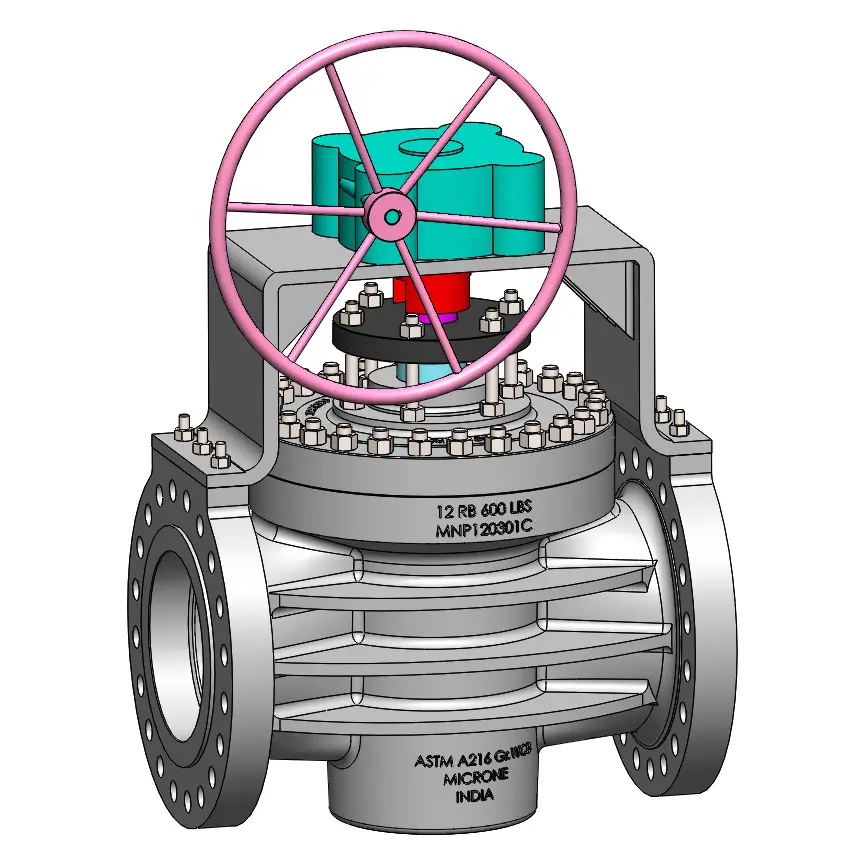

Non-Lubricated Valves are robust in construction and easy to maintain in-line. These valves are sleeved quarter-turn plug valves that achieve sealing through the use of a compressible sleeve as a sealing member. In many applications, they operate virtually maintenance-free for decades. Sleeved plug valves are used for on/off and throttling service. These valves are used in a variety of industries, including petroleum, the chemical industry, pharmacy, chemical fertilizer, and the electric power industry. These valves are bi-directional flow, simple actuation, lightweight, compact design, and multiport configurations, all of which facilitate improved system design.

The inert PTFE sleeve completely surrounds the plug. The sleeve provides a large, circumferential sealing surface from port to port. Open, closed, or rotating, the seal is assured. As the plug rotates, the 360° port lips provide a self-cleaning action to remove scaling and adhering media. Non-lubricant valves are used where less maintenance is required. The friction between the plug cone and body is reduced by sleeves. However, non-lubricated plug valves are limited by the temperature and chemical compatibility of their non-metallic materials. Non-lubricating valves are used to regulate the process fluid, such as sulphur, hydrogen fluoride, or where liquids could be trapped or solidified and potentially clog the valve.

- Plug Valve design complies to API-599 & API-6D.

- Taper Plug Design – Lower operating torque compared to lubricated plug valves.

- Plug Adjustment Option – Enables online maintenance.

- Large PTFE Sleeve – Bubble-tight shutoff.

- No metal-to-metal contact.

- Longer service life.

- Bi-directional in-line bubble-tight seal independent of line pressure.

- Multiple external bubble-tight seals independent of line pressure.

- Direct mechanical three-point adjustment independent of line pressure.

- Independent travel stops.

- Full encapsulation and retention of all leading edges of PTFE sleeve and top seal components.

- Contoured waterway ensures minimum flow turbulence characteristic.

- No body cavities to entrap flow media.

- Positive flow direction indication.

- Fire safe by design and complies to API 607/ ISO 10497.

| Valve Size | 1/2″ – 24″ |

| Valve Type | Sleeved |

| Pressure Class | ANSI 150 / 300 |

| End Connection | RF / RTJ / BW |

| Bore | Full Bore / Reduced Bore |

| Pattern Type | Short / Regular / Venturi |

| Operator | Lever / Gear / Actuator |

| Material | Carbon Steel / Stainless Steel / Duplex / Alloy Steel |

| Operating Temperature | Standard |

| Leakage Class | FCI 70-2 Class VI |

| Design Standard | API 599 |

| Face to Face Standard | ASME B16.10 |

| End Connection Standard | ASME B16.10 |

| Test Standard | API 598 |

| Fire Safe Standard | API 607 / ISO 10497 / API 6FA |

| Certification | EN 10204 3.1 – 3.2 / ISO 15848 Fugitive Emission / 2014-68-EU PED / SIL Capable / IP 67 (Gearbox) |

| 1 | Plug surface and body inner surface materials are compatible with each other. |

| 2 | The actuator selection is automatic. |

| 3 | Strengthened stem packing is optional. |

| 4 | Blow-out-proof stem. |

| 5 | Locking device is optional. |