Offset # 1: The shaft is offset from the seat plane providing an uninterrupted seating surface.

Offset # 2: Centerline of disc is offset from the centerline of the shaft allowing the seal to freely lift off any away from the seat on opening.

Offset # 3: The cone axis is offset from the centerline of the seal to provide a conical sealing surface that allows the seal to rotate in and out of the seat without interface sliding or jamming.

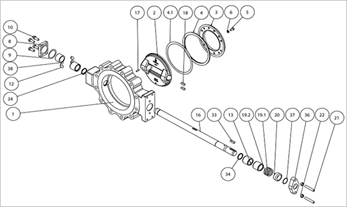

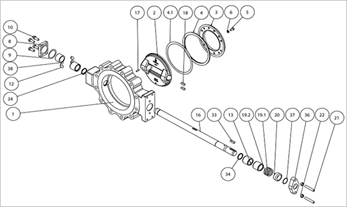

| SL.No | ITEM | MATERIALS |

| 1 | Body | HASTELLOY , 6A, 5A, 4A,NAB, AL-BRZ, CF8M, CF3M, 17-4PH, CA6NM, C12A, |

| 2 | Disc | LCC, LCB, WCC, WCB, INCONEL, NO6625, NO7718, NO8825, NO8926, |

| 3 | Clamp Ring | F51, F53, F60, F316, F316L, F6A, 416, 4140, LF2, A105 |

| 4 | Seal Stack | Graphite & 316 |

| 4.1 | Seal Gasket | Graphite |

| 5 | Cap Screw | B8/ B8m |

| 6 | Lock Washer | 316 |

| 8 | Cover Plate | WCB, WCC, LCB, LCC, CF3, CF8, CF3M,CF8M, 4A, 5A, CK3MCUN , MONEL |

| 9 | Cover Plate Gasket | Graphite |

| 10 | Cap Screw | B8/ B8m |

| 12 | Annular Key | S21800 |

| 13 | Bearing | Carbon Graphite |

| 16 | Shaft | A564 630 H1150M, F316, F51, F53,N06615, N06625, N07718, N08825, N08926, 17-4PH |

| 17 | Spring Pin | SST |

| 18 | Parallel Key | 316 |

| 19.1 | Wiper Ring | Graphite |

| 19.2 | Packing Ring | Graphite |

| 20 | Gland Follower | SS 416 |

| 21 | Stud | B8 |

| 22 | Hex Nut | B8M |

| 33 | Actuator Key | S21800 |

| 34 | BRG Protector | Graphite |

| 36 | Gland Plate | WCB, WCC, LCB, LCC, CF3, CF8, CF3M,CF8M, 4A, 5A, CK3MCUN , MONEL |

| 37 | Retainer Ring | SS 302 |

| 38 | Spacer Ring | SS 316 |